Why Block Ice Machines Are the Optimal Choice for Cold Chain Efficiency

(And How They Can Transform Your Business)

In a world where fresh Norwegian salmon reaches dining tables in Tokyo and life-saving vaccines are delivered to remote villages, the cold chain serves as the invisible backbone of global logistics. While advanced refrigeration systems often dominate the spotlight, there’s a simpler, time-tested solution powering industries worldwide: block ice machines. Let’s explore why this unassuming technology remains indispensable—and how it addresses real-world challenges in your operations.

Block Ice vs. Flake/Cube Ice: Why Density Matters

Before diving into applications, let’s answer a critical question: Why choose block ice over other forms?

- Longer-Lasting Cooling:

A 25kg block ice (standard size) melts 3-5x slower than flake ice under identical conditions, according to the International Institute of Refrigeration (IIR). This makes it ideal for extended transport or regions with unstable power supply. - Stable Temperature Control:

Unlike smaller ice forms, block ice minimizes temperature fluctuations—crucial for sensitive goods like pharmaceuticals. - Cost-Effectiveness:

Reduced melting rates mean fewer ice replenishments, lowering operational costs for long-haul shipments.

4 Practical Applications Where Block Ice Machines Excel

1. Preserving Seafood Freshness from Boat to Market

In the seafood industry, time is the enemy. Fishermen and processors rely on block ice to:

- Rapidly lower fish temperatures post-catch (critical to prevent bacterial growth).

- Maintain 0–4°C environments during storage and transport, even in tropical climates.

- Reduce spoilage rates by up to 30% compared to untreated storage (FAO, 2021).

Real-World Example: Small-scale fisheries in Southeast Asia use portable block ice machines on boats to extend shelf life and access premium markets.

2. Reducing Agricultural Food Waste

For farmers shipping perishables like berries or leafy greens, a single temperature spike can ruin entire batches. Block ice helps by:

- Pre-cooling produce before transit, a step proven to extend freshness by 40% (USDA).

- Serving as a backup cooling source when refrigeration fails—common in regions with unreliable infrastructure.

Case Study: A Kenyan avocado exporter reduced post-harvest losses by 22% after adopting block ice pre-cooling stations.

3. Ensuring Safety in Meat & Poultry Logistics

Contaminated meat costs the global economy billions annually. Block ice mitigates risks by:

- Creating stable cold environments in non-refrigerated trucks (common in short-haul deliveries).

- Complying with HACCP standards for food safety during loading/unloading.

4. Emergency & Pharmaceutical Uses

When power grids fail during disasters or in rural clinics, block ice becomes a lifesaver:

- Preserving vaccines and medications where electric cold storage isn’t feasible (WHO recommends block ice for last-mile vaccine delivery).

- Cooling emergency blood supplies during disaster relief operations.

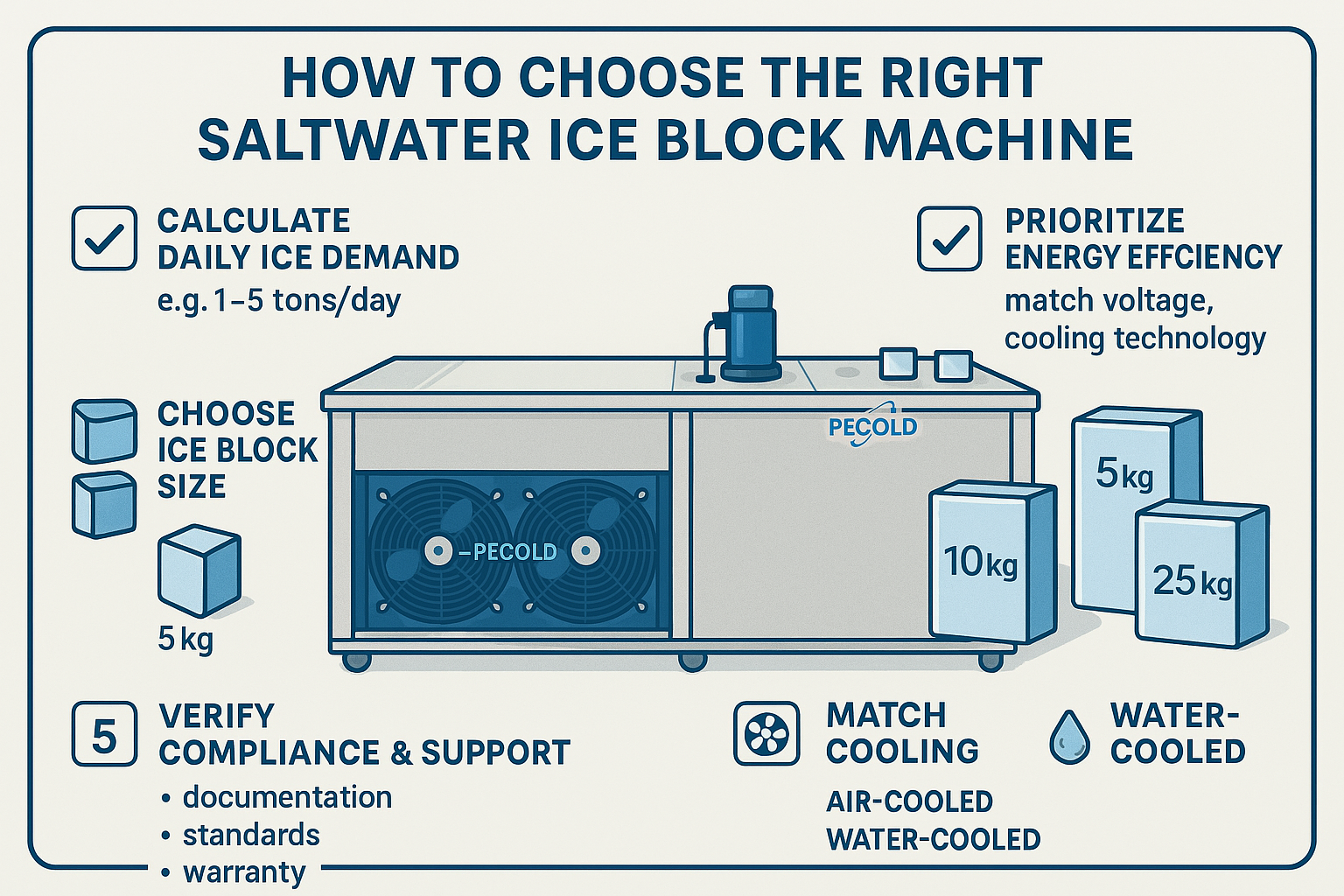

Choosing the Right Block Ice Machine: 2 Critical Factors

Not all ice machines are created equal. Prioritize these elements for cold chain success:

- Durability Over Advanced Features:

Harsh environments (e.g., fishing vessels or tropical farms) demand corrosion-resistant materials like stainless steel. Opt for IP54-rated units for dust/moisture protection. - Energy Efficiency = Lower Total Cost of Ownership:

Machines with high-quality compressors reduce energy consumption by up to 40%, slashing long-term costs.

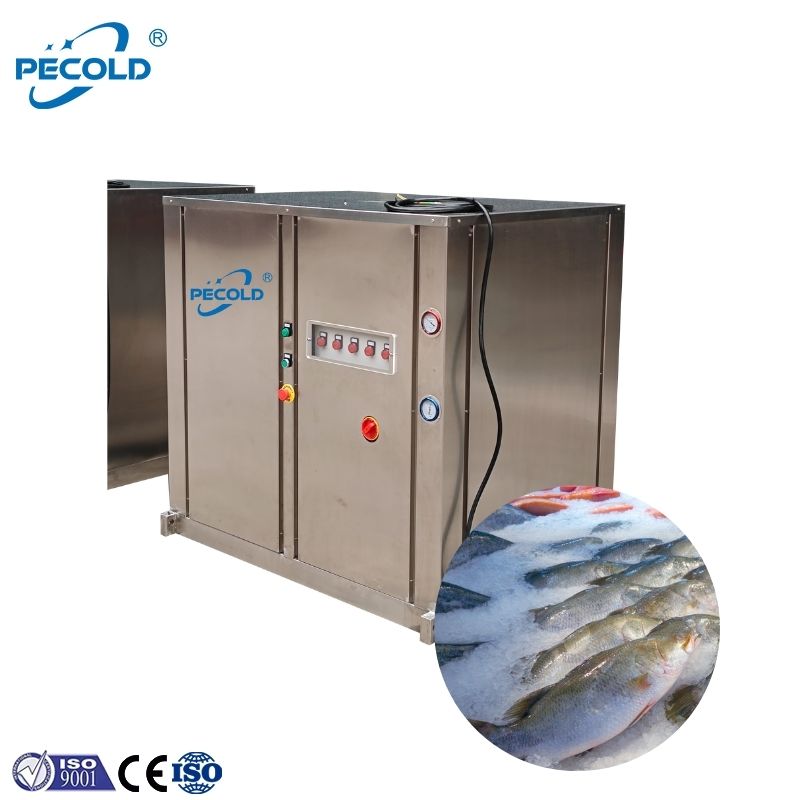

Why Pecold? Where Engineering Meets Practicality

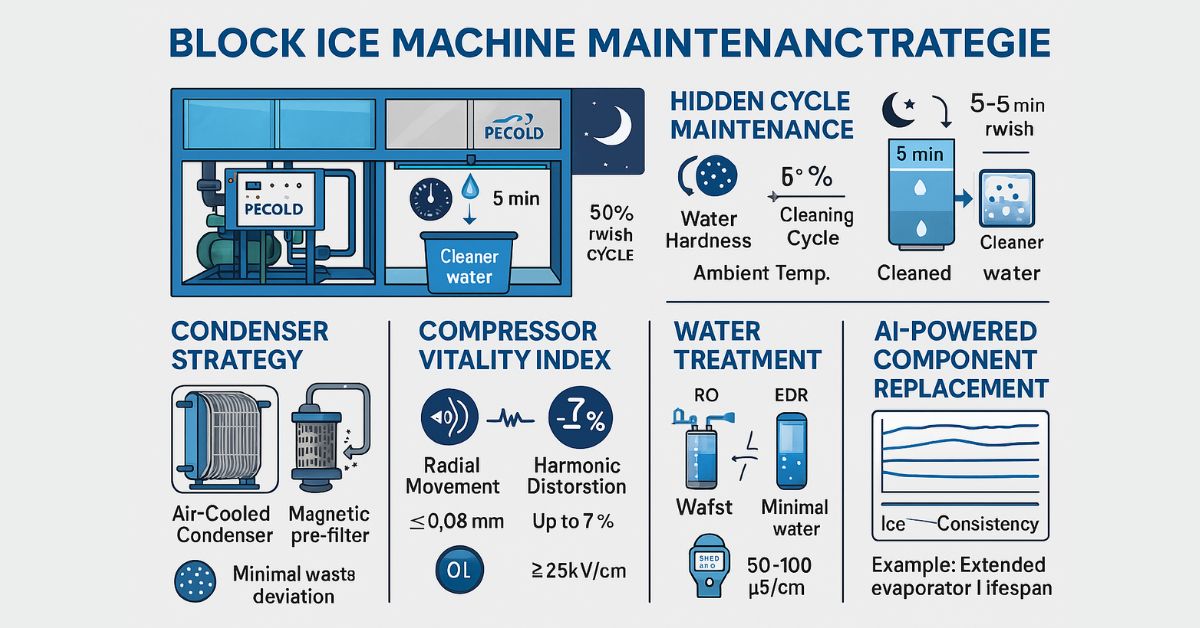

At Pecold, we design block ice machines for real-world reliability, not just specs. Here’s how we tackle common challenges:

- Problem: Frequent breakdowns in humid conditions.

Solution: Premium stainless steel construction with dual-layer insulation. - Problem: High electricity costs.

Solution: CE-certified models with energy-efficient compressors.

Final Takeaway: Block Ice Machines Are Essential, Not Outdated

While AI-driven cold chain tech grabs headlines, block ice machines remain a pragmatic choice for businesses prioritizing reliability, cost control, and flexibility. Whether shipping salmon across continents or delivering vaccines to remote communities, this technology bridges gaps that high-tech systems alone cannot.

Ready to Optimize Your Cold Chain with Block Ice?

References:

- International Institute of Refrigeration (IIR). (2020). The Role of Refrigeration in Worldwide Nutrition.

- Food and Agriculture Organization (FAO). (2021). Reducing Post-Harvest Losses in Fisheries.

- USDA. Best Practices for Produce Cold Chain Management.