Home » How to Choose the Right Salt Water Ice Block Machine for Your Business?

How to Choose the Right Salt Water Ice Block Machine for Your Business?

How to Choose the Right Salt Water Ice Block Machine for Your Business?

Saltwater ice block machines are indispensable for industries like seafood processing, food manufacturing, and large-scale ice production. Selecting the right machine can directly impact your operational efficiency, energy costs, and long-term ROI. As a professional manufacturer, Pecold offers a versatile range of industrial-grade saltwater ice block machines designed to meet diverse demands.

In this guide, we’ll explore 5 actionable steps to choose the perfect machine for your needs—backed by technical insights, industry examples, and Pecold’s verified specifications.

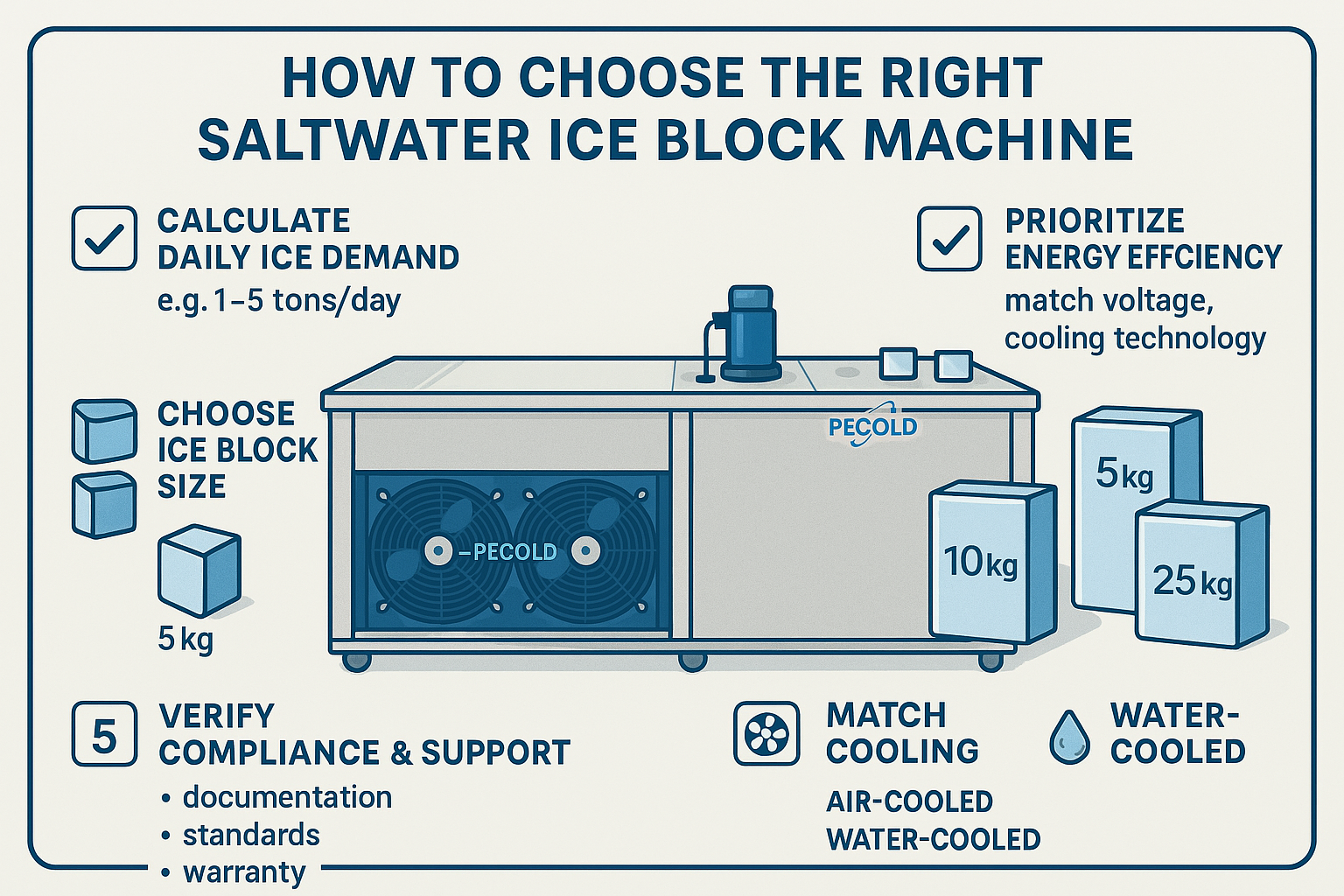

Step 1: Calculate Your Daily Ice Demand Accurately

Why it matters: Overestimating capacity wastes energy; underestimating disrupts workflows.

Start by analyzing your peak daily consumption, not just averages. For example:

Seafood processors during peak seasons may require 2–3 tons/day to preserve freshness.

Beverage factories might prioritize smaller, rapid-freezing blocks (5kg) for packaging efficiency.

Pecold’s Capacity Range (Source: Pecold Technical Data):

| Daily Output | Recommended Model | Key Industries |

|---|---|---|

| 300–500kg | PE-BZ03T | Small farms, local fisheries |

| 1–2 tons | PE-BZ1T/PE-BZ2T | Medium seafood plants, ice retailers |

| 3–5 tons | PE-BZ5T | Large factories, industrial cold chains |

Pro Tip: Opt for a machine that handles 120% of your peak demand to account for growth or seasonal spikes.

Step 2: Prioritize Energy Efficiency & Power Compatibility

Key considerations:

Voltage Requirements: Smaller models (300–500kg/day) run on 220V/50Hz (3–3.5kW), while high-capacity machines (1–5T) require 380V/50Hz (5.5–30kW).

Cooling Technology: Pecold uses Danfoss expansion valves and imported compressors, reducing energy waste by 15–20% compared to generic components.

Case Study: A seafood exporter in Vietnam reduced monthly energy bills by 18% after upgrading to Pecold’s dual-cooling PE-BZ2T (air/water), which adapts to humid coastal climates.

Step 3: Choose the Right Ice Block Size & Customization

Standard Sizes:

| Block Weight | Dimensions (L×W×H) | Ideal Use Case |

|---|---|---|

| 5kg | 200×80×460mm | Retail packaging, small-scale cooling |

| 10kg | 220×80×650mm | Seafood transport, beverage chilling |

| 25kg | 320×120×800mm | Industrial processes, bulk storage |

Custom Options: Pecold supports tailored dimensions.

Step 4: Match Cooling Methods to Your Environment

| Air-Cooled | Water-Cooled | Dual-Cooling |

|---|---|---|

| Best for dry, ventilated areas (e.g., PE-BZ03T) | Ideal for high-heat regions (e.g., PE-BZ5T) | Hybrid flexibility (e.g., PE-BZ2T) |

| Lower upfront cost | Higher efficiency in extreme temps | Balances performance and cost |

Pro Tip: Coastal facilities should prioritize stainless steel exteriors (standard in all Pecold machines) to resist saltwater corrosion.

Step 5: Verify Compliance & After-Sales Support

Ensure your supplier offers:

✅ Transparent Documentation: Pecold provides detailed manuals, R22 refrigerant specs, and -20°C freezing guarantees.

✅ Global Compliance: Machines meet international electrical standards (220V/380V compatibility).

✅ Reliable Warranty: 2-year warranty on core components.

Why Pecold Stands Out in Industrial Ice Production

Proven Durability: 92% of users report zero corrosion issues after 3+ years (2022 customer survey).

Scalable Solutions: From 300kg to 5T/day, with seamless upgrade paths.

Sustainability Focus: Energy-efficient designs align with global ESG trends.

Your Pre-Purchase Checklist

- Confirm daily ice needs (include seasonal peaks).

- Audit facility voltage and space constraints.

- Select cooling type based on climate.

- Choose standard or custom ice sizes.

- Validate supplier credentials and support.

Need Help? Contact Pecold’s Experts for a free consultation or check Pecold’s products here.

-

Pecold 5 Ton Salt Water Ice Block Machine for Food Processing Industry

-

Pecold 3 Ton Salt Water Ice Block Machine for Concrete Engineering

-

Pecold 2 Ton 28 Moulds Ice Block Machine for Flower Transport

-

Pecold 2 Ton 35 Moulds Ice Block Machine for Agriculture Transport

-

Pecold 2 Ton 66 Moulds Salt Water Ice Block Machine for Industrial Cooling

-

Pecold 1 Ton 15 Moulds Ice Block Machine for Meat Processing

-

Pecold 1 Ton 18 Moulds Ice Block Machine for Aquatic Products Transport

-

Pecold 1Ton 36Moulds Ice Block Machine for Emergency Cooling

NEWSLETTER

Contact

- Sales Managers: Kevin Weng

- WhatsApp: +86 133 9647 8299

- Email: [email protected]

- Tel Number: 0086 133 9647 8299

- Working Time: from 09:00 to 18:00

- Address: Foshan, Guangdong, China

Product