Home » Why Flake Ice Machines Are Essential for Seafood Quality Preservation

Why Flake Ice Machines Are Essential for Seafood Quality Preservation

Why Flake Ice Machines Are Essential for Seafood Quality Preservation

How Fisheries & Processors Can Prevent Spoilage & Maximize Profits

In the $150 billion global seafood industry, temperature management isn’t just a best practice—it’s the difference between premium profits and costly waste. With 35% of seafood lost to spoilage annually (FAO 2022), fisheries increasingly rely on flake ice’s unique properties to protect delicate proteins. Let’s examine why this ice format dominates marine cold chains.

What Makes Flake Ice Ideal for Seafood?

Unlike cubed or block ice, flake ice provides 3 scientific advantages:

- Faster Cooling = Safer Products

At 1.6-2.5mm thickness, flake ice creates a “protective shell” around fish, achieving 2X faster cooling than block ice (Journal of Food Engineering). This rapid temperature drop below 4°C (40°F)—the FDA’s critical safety threshold—slows bacterial growth by 90%. - Zero Physical Damage

Soft, moldable flakes prevent bruising in high-value species like tuna ($300/kg bluefin) or shellfish—a key reason 78% of Japanese sushi-grade processors use flake ice exclusively (2023 Seafood Expo Survey). - Space-Efficient Cooling

Irregular shapes fill 100% of container gaps, maintaining stable temperatures during 48-hour shipments—critical for meeting EU/Asian import regulations.

4 Critical Applications Where Flake Ice Protects Value

- Dockside First Aid

Applying ice within 30 minutes of catch reduces histamine formation in oily fish by 60% (NOAA Guidelines). Portable flake machines allow immediate treatment on trawlers. - Processing Line Efficiency

Pre-chilling with 1:1 ice-to-fish ratio extends fillet shelf life by 3-5 days. Automated ice blending systems (like Pecold’s PCL-20T) cut labor costs by 40%. - Cold Chain Integrity

Flake ice’s 30% longer melt time vs. cubes ensures consistent humidity during air/sea freight—vital for preventing dehydration in scallops and shrimp. - Disaster Preparedness

On-site ice production provides backup cooling during power outages, protecting $50k+ cold storage inventories.

Choosing Your Flake Ice Machine: 5 Data-Driven Tips

- Match Capacity to Catch Volumes

Small boats: 1-3 ton/day

Processing plants: 10-30 ton/day - Verify Energy Efficiency

Look for ≤0.15 kWh/kg ice consumption - Prioritize Food Safety Certifications

Must-have: NSF/CE, ISO 22000

Emerging standard: EHEDG hygienic design - Automate for Consistency

Features like auto-defrost cycles reduce temperature fluctuations by ±0.5°C vs manual systems. - Calculate True ROI

Pecold's Proven Solutions for Marine Applications

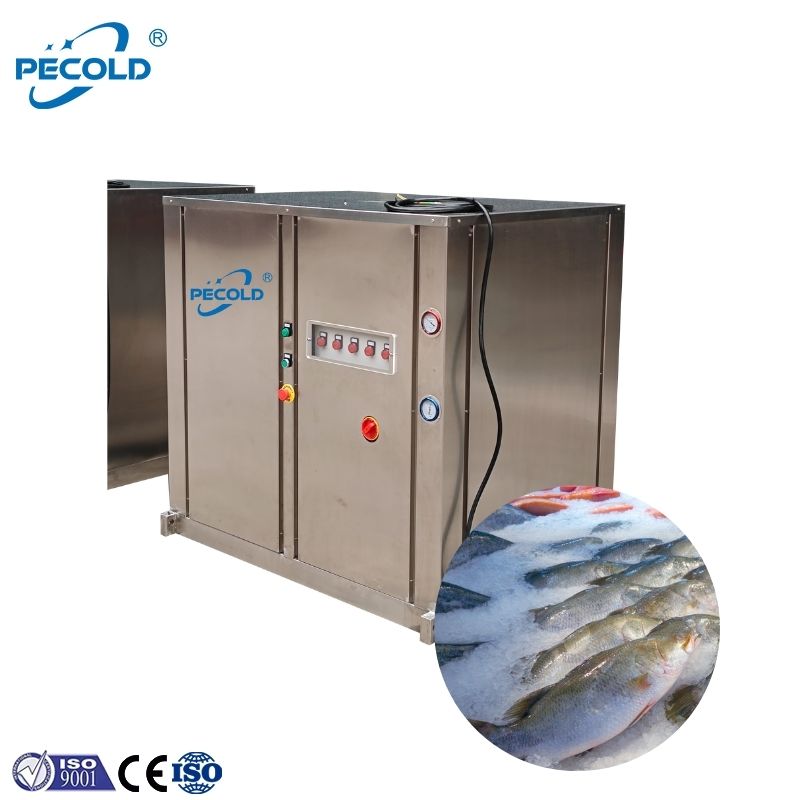

With 140+ fisheries clients across 15 countries, we engineer flake ice systems that address real-world challenges:

✔️ Corrosion Resistance

316L stainless steel construction withstands saltwater environments.

✔️ Smart Monitoring

Remote IoT sensors track ice temp/humidity 24/7—ideal for HACCP compliance.

✔️ Scalable Infrastructure

From boat-mounted mini-units to 30-ton/day industrial plants.

[Get Customized Proposal]

NEWSLETTER

Contact

- Sales Managers: Kevin Weng

- WhatsApp: +86 133 9647 8299

- Email: [email protected]

- Tel Number: 0086 133 9647 8299

- Working Time: from 09:00 to 18:00

- Address: Foshan, Guangdong, China

Product