Home » Why Tube and Cube Ice Machines Are Best for Food & Beverage Industry

Why Tube and Cube Ice Machines Are Best for Food & Beverage Industry

Why Tube and Cube Ice Machines Are Best for Food & Beverage Industry

1. Superior Cooling Efficiency: Less Melt, Better Performance

Tube ice, with its hollow cylindrical shape, offers a large surface area that chills beverages rapidly while resisting quick melting. This makes it ideal for high-volume settings like bars or quick-service restaurants, where speed and presentation matter.

Cube ice, known for its dense structure, melts slower—perfect for cocktails or soft drinks where flavor preservation is key. For example, a 2022 industry survey noted that 78% of bartenders prefer cube ice for premium drinks due to its minimal dilution (Source: Beverage Industry Trends Report).

2. Hygiene & Compliance: Meeting Global Safety Standards

Food safety regulations, such as the EU’s Regulation (EC) No 852/2004, mandate strict hygiene practices. Modern tube and cube ice machines address this with:

- Fully enclosed production systems to prevent contamination.

- Food-grade stainless steel construction (e.g., Pecold’s machines include cleaning cycles for consistent sanitation).

Industries like seafood processing or juice manufacturing benefit from these features, ensuring compliance and reducing recall risks.

3. Versatility Across Applications

From farm-to-table supply chains to hotel buffets, both ice types adapt seamlessly:

- Tube ice: Ideal for preserving perishables during transport or cooling bottled beverages.

- Cube ice: Enhances drink presentation in cafes or event catering.

This versatility allows businesses to standardize ice production across multiple workflows without investing in separate equipment.

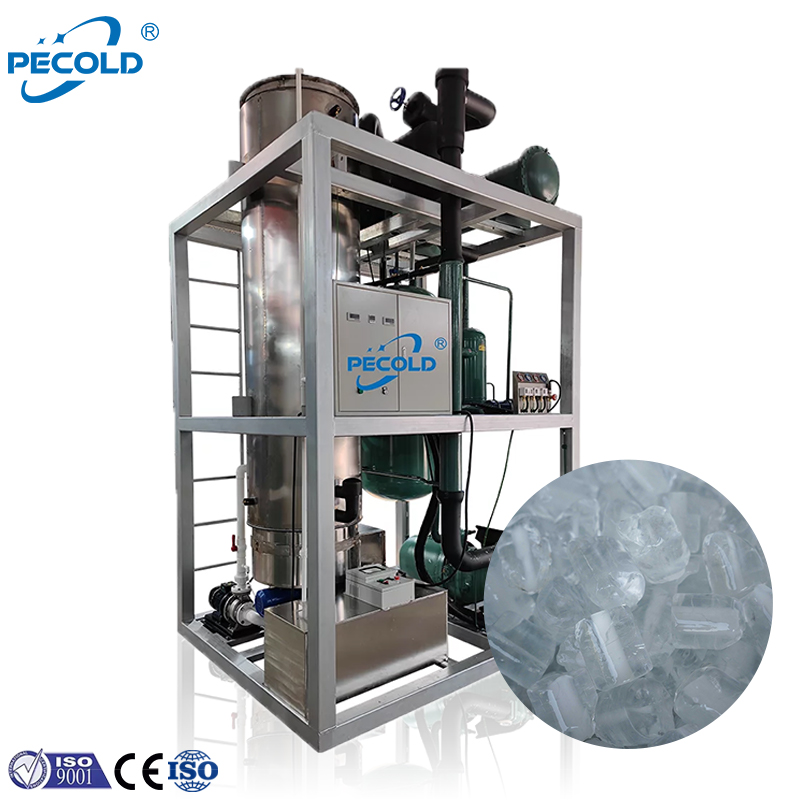

4. High-Capacity Output for Demanding Operations

Restaurants and bottling plants require machines that keep up with peak demand. For instance:

- Pecold’s tube ice machines produce 1–50 tons daily, suited for large seafood processors.

- Cube ice models (500kg–5 tons/day) cater to mid-sized venues like hotels.

Energy-efficient designs and low maintenance further reduce operational costs—a key factor for ROI-focused businesses.

5. Seamless Integration with Automation

Modern F&B facilities prioritize streamlined workflows. Tube and cube ice systems can integrate with:

- Automated packaging lines.

- Centralized cooling systems.

This minimizes manual handling, cuts labor costs, and boosts efficiency—critical for scaling operations.

Choosing the Right Ice Machine: A Strategic Investment

While flake or block ice have niche uses, tube and cube ice machines deliver unmatched balance in performance, safety, and adaptability. When selecting equipment, consider:

- Daily production needs (e.g., a 10-ton/day machine for large-scale seafood exporters).

- Compliance requirements (e.g., NSF-certified models for EU markets).

- Energy ratings to align with sustainability goals.

How Pecold Supports Your Ice Production Needs

At Pecold, we engineer industrial-grade ice machines tailored for F&B professionals. Our solutions include:

- Customizable solutions for factories and other business.

- 24/7 technical support to minimize downtime.

For a detailed cost-benefit analysis or case studies (e.g., how a Vietnam seafood plant boosted output by 30% with our tube ice systems), contact our team for data-driven insights.

NEWSLETTER

Contact

- Sales Managers: Kevin Weng

- WhatsApp: +86 133 9647 8299

- Email: [email protected]

- Tel Number: 0086 133 9647 8299

- Working Time: from 09:00 to 18:00

- Address: Foshan, Guangdong, China

Product